OIL FREE SCREW

Hitachi Social Innovation

-Environment Friendly,High Standard Oil-Free Rotary Screw Compressor(DSP)

Premium Air Quality

True Oil-Free Air at Class 0 Level

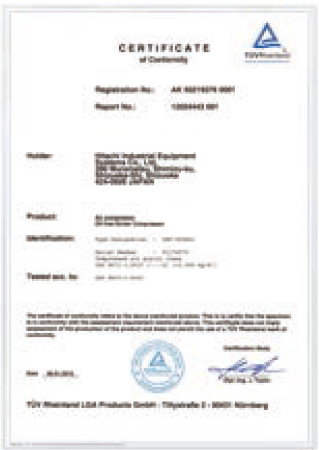

Test and analysis of condensation of oil in the discharge air of Hitachi Oil-free Screw Compressor (DSP) are implemented by third party (TÜV) based on ISO8573-1 standard. By the test result, oil contained in the discharge air of Hitachi DSP is proved and certified as the highest level of quality air “Class 0”.

ISO8573-1:2010 CLASS 0 TÜV Certification TÜV (The Technische Überwachungs Verein), a Germany based international test service provision third-party on aspects of technical safety and quality evaluation, is globally well-reputed on its neutrality and expertise as well as its strictness in testing.

Industry Standard in Energy-Saving,Enviornment Friendly and High Quality

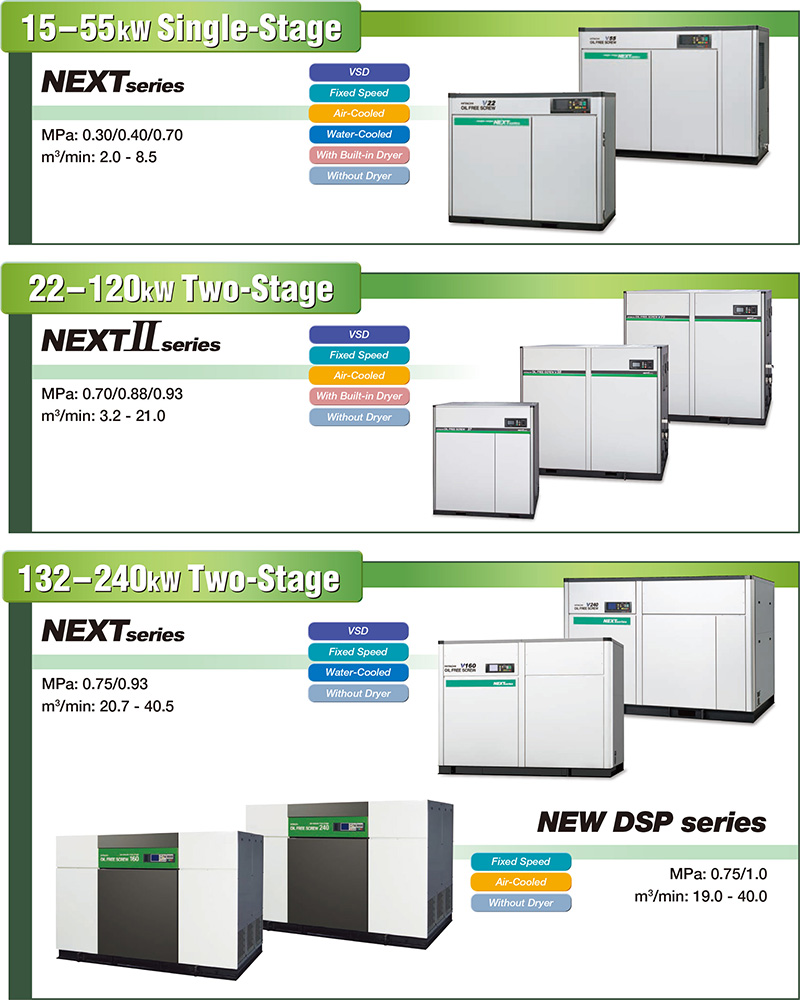

-From small to large,Full Line-up(15-240kW)

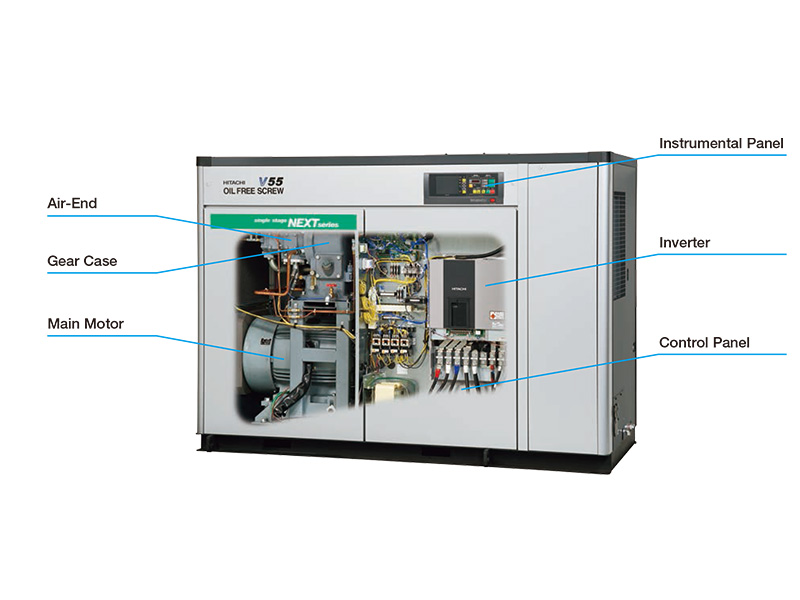

Two-Stage,Air-Cooled(22/37/45/55/75/90/100/120kW)

*The image described above has been modified.

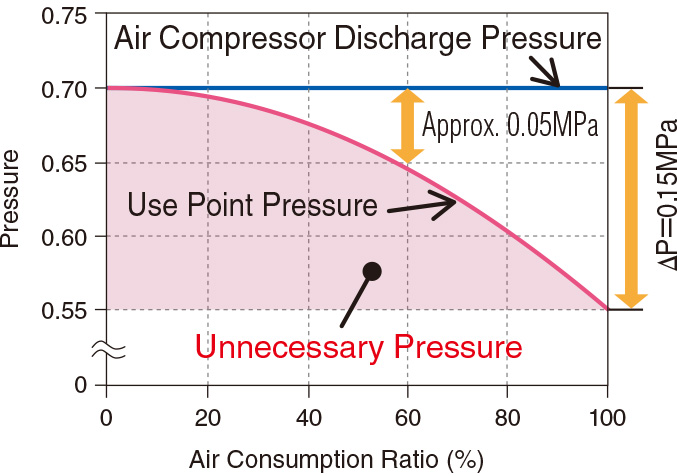

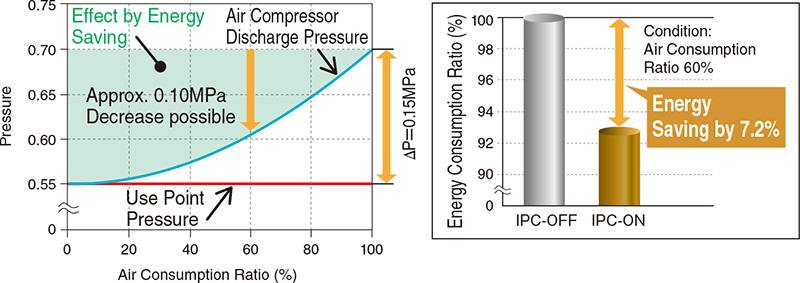

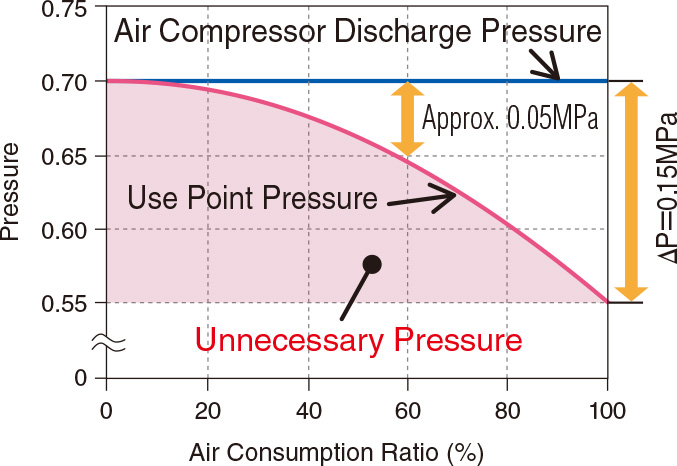

IPC Control (Intelligent Pressure Control)

By estimating use point pressure in accordance with air consumption, IPC control decreases discharge pressure during low load operation, which enables Energy-Saving.

Example of effect by IPC

Conditions

- Air compressor: DSP-37VATN2

- Piping pressure loss during full load: 0.15MPa

- Control pressure setting: 0.70MPa

- Use point pressure during full load: 0.55MPa

Graph of pressure change (Theoretical values)

①IPC-OFF (Conventional inverter control model)

②IPC-ON (NEXT II series)

*Due to estimation control, use point pressure varies in accordance with use conditions.

*IPC control range of the constant speed unit is air consumption ratio of 50% or more.

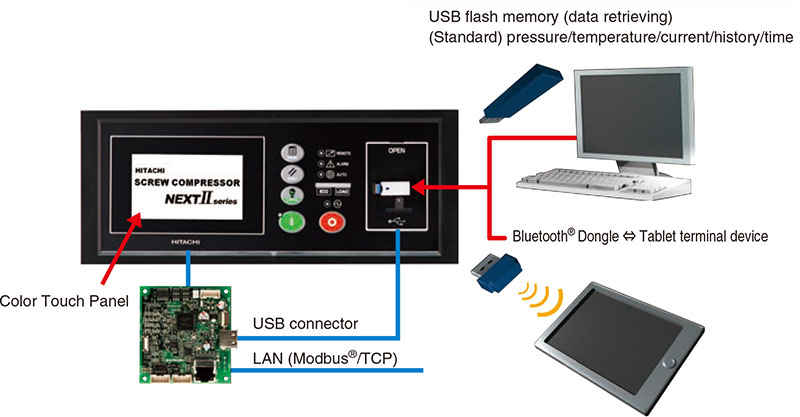

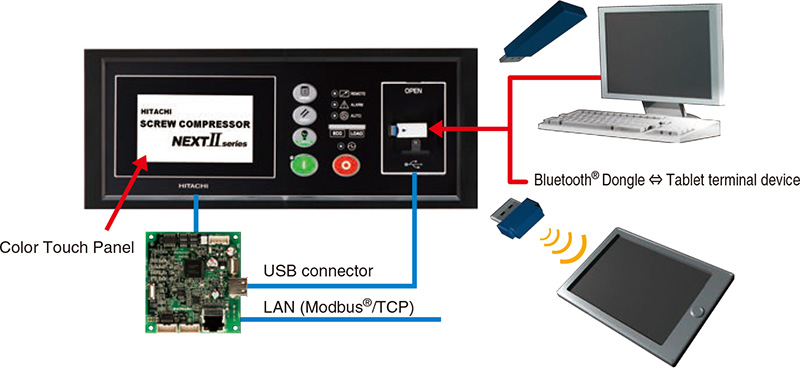

IT Communication Functions

USB Flash Memory Possible for Data Logging

*Necessary to prepare aUSB flash memory device(5.5cm or smaller) on user’s side.*Operation data for one day is approximately 400kB. (For reference)

USB flash memory (data retrieving) (Standard) pressure/temperature/current/history/time

Web Server Function via Bluetooth®

*Necessary to prepare a Bluetooth® USB dongle on your side.

*For setting changes, part of the items are applicable.

Modbus® Communication

Open network serial communication

Modbus® /RTU is supported as standard

*Modbus® /TCP support is optional.

*Bluetooth is the registered tradmark of Bluetooth SIG, Inc (US). *Modbus is the registered trademark of Schneider Automation Inc.

Two-Stage,Water-Cooled(45/55/75/90/100/120kW)

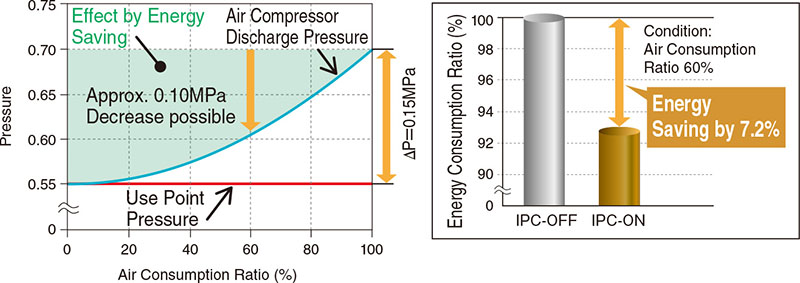

IPC Control (Intelligent Pressure Control)

By estimating use point pressure in accordance with air consumption, IPC control decreases discharge pressure during low load operation, which enables Energy-Saving.

Patent JP4425768 and others

Example of effect by IPC

Conditions

- Air compressor: DSP-37VATN2

- Control pressure setting: 0.70MPa

- Use point pressure during full load: 0.55MPa

- Piping pressure loss during full load: 0.15MPa

Graph of pressure change (Theoretical values)

①IPC-OFF (Conventional inverter control model)

②IPC-ON (NEXT II series)

*Due to estimation control, use point pressure varies in accordance with use conditions.

*IPC control range of the constant speed unit is air consumption ratio of 50% or more.

IT Communication Functions

USB Flash Memory Possible for Data Logging

*Necessary to prepare aUSB flash memory device(5.5cm or smaller) on user’s side.

*Operation data for one day is approximately 400kB. (For reference)

USB flash memory (data retrieving)

(Standard) pressure/temperature/current/history/time

Web Server Function via Bluetooth®

*Necessary to prepare a Bluetooth® USB dongle on your side.

*For setting changes, part of the items are applicable.

Modbus® Communication

Open network serial communication

Modbus® /RTU is supported as standard

*Modbus® /TCP support is optional.

*Bluetooth is the registered tradmark of Bluetooth SIG, Inc (US).

*Modbus is the registered trademark of Schneider Automation Inc.